How to chosse Industrial Gear Oil in Nigeria : Maintenance for Factory & Plant Machinery

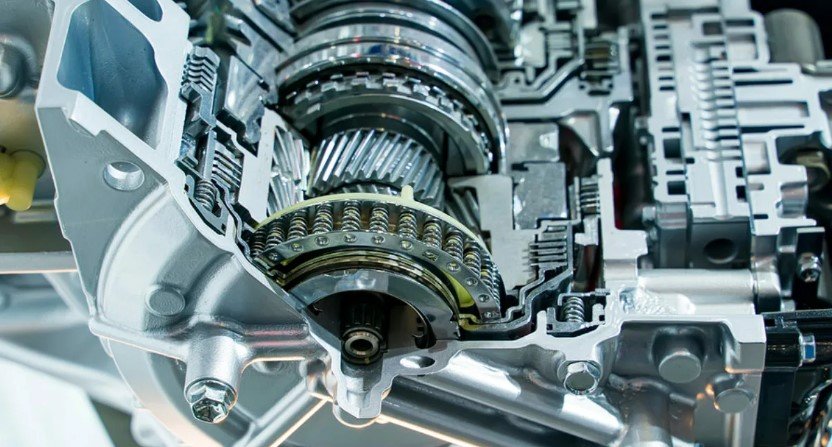

In the relentless environment of Nigerian industry—from bustling Lagos factories to resource plants in the Niger Delta—the heartbeat of productivity is your machinery. Conveyor belts, heavy-duty gearboxes, crushers, and milling equipment face immense pressure, compounded by unique local challenges like extreme heat, humidity, inconsistent power supply causing start-stop cycles, and the ever-present need for cost-effective maintenance. At the core of protecting these critical assets lies a deceptively simple component: industrial gear oil.

Choosing the wrong lubricant is not just a procurement error; it’s a direct threat to operational efficiency, machinery lifespan, and ultimately, your bottom line. This comprehensive guide, powered by the engineering expertise behind R8 Drive Oil, will walk you through the critical steps to select the perfect gear oil, ensuring your plant runs smoother, for longer.

Understanding the Role of Gear Oil: More Than Just Lubrication

Industrial gear oil is a precisely engineered fluid designed to perform multiple vital functions within gear systems:

Lubrication: Forms a protective film between metal surfaces to minimize friction and wear.

Cooling: Dissipates heat generated by gear meshing and friction.

Protection: Guards against rust, corrosion, and the formation of sludge or varnish.

Power Transmission: Acts as a hydraulic medium in some systems.

Contaminant Management: Suspends wear particles and other contaminants until they can be filtered out.

Using a sub-standard or incorrect oil accelerates wear, leads to premature component failure, increases energy consumption, and causes unplanned downtime—a cost Nigerian manufacturers can ill afford.

The 6-Step Decision Framework for Selecting Gear Oil in Nigeria

Follow this structured approach to make an informed, reliable choice for your machinery.

Step 1: Decipher the Manufacturer’s Manual & OEM Specifications

The manufacturer’s manual is your primary guide. It specifies the required viscosity grade (e.g., ISO VG 220, ISO VG 68) and performance specifications (e.g., AGMA, DIN, or specific OEM standards like Siemens, Flender, or David Brown). Your first duty is to match these specifications. R8 Drive Oil formulations are engineered to meet and exceed major international and OEM specifications, ensuring compliance and warranty preservation.

Step 2: Define the Operating Conditions (The Nigerian Context)

This is where local expertise is crucial. Assess your specific operating environment:

Load & Shock Loading: High-torque applications like crushers or ball mills require oils with extreme pressure (EP) additives to prevent scoring and pitting under heavy loads.

Ambient Temperature & Heat: Nigerian ambient temperatures can be extreme. High temperatures thin out oil; you may need a higher viscosity grade or a high thermal stability oil. R8 Drive Oil’s advanced formulation resists oxidation and thermal breakdown even in sweltering conditions.

Moisture & Contamination Risk: In humid climates or wash-down areas, gear oil must have excellent demulsibility (ability to separate from water) and superior anti-rust properties. Water ingress is a leading cause of gear failure.

Continuous vs. Intermittent Operation: Machinery subjected to frequent starts and stops—common with power fluctuations—experiences more wear during startup. Oils with strong anti-wear film strength are vital.

Step 3: The Critical Choice – Viscosity and Viscosity Index

Viscosity is the oil’s resistance to flow. It is the single most important property.

Too low viscosity: Leads to metal-to-metal contact, wear, and noise.

Too high viscosity: Causes fluid friction, overheating, and increased energy consumption. The Viscosity Index (VI) measures how much the viscosity changes with temperature. A high VI oil (like many in the R8 Drive Oil range) maintains its protective viscosity better across a wide temperature range—from a cool morning in Jos to a scorching afternoon in Kano—providing consistent protection.

Step 4: Selecting the Right Additive Package & Type

Extreme Pressure (EP) Gear Oils: Essential for most industrial applications involving high loads. They contain sulfur-phosphorus additives that form a protective layer on gear teeth.

Synthetic Gear Oils: While having a higher initial cost, synthetic base oils (like those used in premium R8 Drive Oil grades) offer superior performance: wider temperature range, longer oil life, better efficiency, and lower friction. They are highly cost-effective for critical, high-value, or hard-to-reach equipment.

Inhibited Gear Oils: Used for lighter loads, primarily offering anti-rust and anti-oxidation protection.

Step 5: Compatibility with Seals and Other Lubricants

Ensure the new gear oil is compatible with elastomeric seals (like nitrile or polyacrylate) in your gearbox to prevent leaks. If you are considering a switch from a mineral-based to a synthetic fluid like R8 Drive Oil, a compatibility check or a gradual flush procedure is recommended.

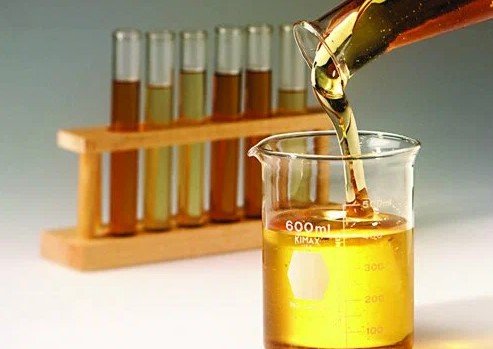

Step 6: Prioritize Quality, Filtration, and Analysis

Never compromise on quality for price. Counterfeit or adulterated lubricants are a pervasive threat in the market. Source your oils from authorized and reputable distributors.

Proper Filtration: Use recommended filters during top-up and changes.

Oil Analysis: Implement a routine used oil analysis program. Monitoring wear metals, viscosity change, and contamination in your R8 Drive Oil is the equivalent of a blood test for your machinery. It enables predictive maintenance, allowing you to fix issues before they cause catastrophic failure.

Why R8 Drive Oil is the Engineered Choice for Nigerian Industry

In a market flooded with options, R8 Drive Oil stands apart as a solution built for the specific demands of Africa’s industrial powerhouse.

Locally Attuned Formulations: Our products are designed with the Nigerian climate and operational stressors front of mind.

Uncompromising Quality Assurance: Every batch of R8 Drive Oil meets stringent international standards, guaranteeing purity and performance integrity.

Extended Drain Intervals: Our advanced additive technology and synthetic options lead to longer oil service life, reducing disposal costs and downtime.

Superior Protection: Enhanced anti-wear, anti-foam, and rust inhibition properties directly combat the most common causes of gearbox failure in local plants.

Technical Support & Expertise: Choosing R8 Drive Oil grants you access to our network of lubrication engineering specialists who can assist with selection, maintenance audits, and oil analysis interpretation.

Best Practices for Gear Oil Maintenance in Your Factory

Selection is only half the battle. Proper maintenance is key:

Storage: Store oil drums indoors or under cover, on their sides, to prevent water ingress and contamination. Practice first-in, first-out (FIFO) inventory.

Handling: Use clean, dedicated pumps and transfer containers. Never use open buckets or funnels.

Topping Up: Always top up with the same brand and grade of oil (e.g., R8 Drive Oil ISO VG 220) to avoid additive clash.

Change-Outs: Follow recommended intervals but let condition monitoring (oil analysis) be your ultimate guide.

Record Keeping: Maintain meticulous logs for each gearbox: oil type, change dates, top-up quantities, and analysis reports.

Conclusion: An Investment, Not a Cost

Selecting the right industrial gear oil is a strategic technical decision that safeguards your most valuable production assets. In the challenging operating landscape of Nigeria, it pays to partner with a specialized, trustworthy brand.

By following this guide—prioritizing OEM specs, understanding your environment, focusing on viscosity, and insisting on high-quality, context-engineered products like R8 Drive Oil—you transform your lubrication practice from a routine maintenance task into a powerful driver of plant reliability, productivity, and profitability.

Protect Your Drive. Power Your Productivity. Choose R8 Drive Oil.

How to chose Industrial Gear Oil in Nigeria : Maintenance for Factory & Plant Machinery

How to chosse Industrial Gear Oil in Nigeria : Maintenance for Factory & Plant Machinery Get In Touch In the relentless environment of Nigerian industry—from

How to Choose Between Synthetic and Conventional Transmission Oil In Nigeria?

How to Choose Between Synthetic and Conventional Transmission Oil In Nigeria? Get In Touch In Nigeria, where the vehicle is not merely a mode of

How to Choose the Most Durable Diesel Engine Oil in Nigeria?

How to Choose the Most Durable Diesel Engine Oil in Nigeria? Get In Touch In Nigeria’s demanding operating environment—from Lagos traffic to northern desert routes—diesel

Sourcing Quality Hydraulic Oil in Nigeria: A Buyer’s Checklist

Sourcing Quality Hydraulic Oil in Nigeria: A Buyer’s Checklist Get In Touch In the dynamic and demanding landscape of Nigerian industry—spanning robust sectors like construction,

Solve This: Top Signs Your Car Needs a Fuel Injector Cleaner in Nigeria

Solve This: Top Signs Your Car Needs a Fuel Injector Cleaner in Nigeria Get In Touch In Nigeria’s demanding driving conditions—from Lagos traffic jams to

Group III Base Oil Suppliers Nigeria | High Viscosity Index Base Stocks

Group III Base Oil Suppliers Nigeria | High Viscosity Index Base Stocks Get In Touch The Nigerian industrial and automotive landscape is undergoing a silent